Australia So Much to See

An interview with a former Broken Hill Miner

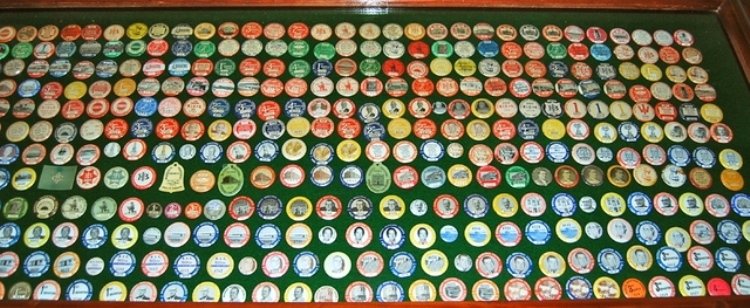

There were some strange rules applied in the past. Each member of the union had to be a paid-up member and there was a quarterly badge

show. Union members were issued with a badge. They had to wear the badge on their work clothes for the shift stated on the badge.

Wrong badge or no badge meant that the worker was sent home, effectively fining the worker that day’s pay.

We once had a two day strike because a miner was sent home for calling his boss a knuckle head.

The Union movement in Broken Hill produced their

own newspaper to keep the workers up to date with union news. Each unionist had to pay for the Barrier Daily Truth to be delivered

six days a week. If there were more than one unionist in the house they all got a paper. The Barrier Daily Truth is still producing

a local newspaper six days a week in Broken Hill.

What did you do when you started in the mine?

I started as a scout

and worked with miners for 400 shifts to learn the jobs.

In the older methods on mining the crusher was at the bottom of the

mine next to a shaft. Skips run up and down to hoist the ore. Last mine I was at it was fourteen ton at a time every 2.5 minutes

from 1,200 metres down.

How were the skips lifted?

There are Winders. Bloody big winches on the surface with two skips

in balance. One filling as one empties. Empty goes down as full goes up. It whistles as one goes by. They have steel runners

on two sides that guide them.

I have been down the full 1,200 metres on top of one of those skips. A stage is placed on

top with communication gear. Two men stand on top and give signals with bells. Four is men on, and two is ready to go

down. If you want to stop to inspect anything you give one bell.

It is different now. The old methods in mining have

now been overtaken with technology. The early days of supporting the roof with timber and using battery powered locomotives underground

has been phased out and long hole mining, fifty tonne dump trucks and loaders capable of lifting 26 tonnes of ore are now used. Some of the underground operations are now controlled from the surface using video cameras and computers.

Now retired, I still

miss the larrikins that I worked with. I have memories of explosives going off whilst we were working in the area, and of being lowered

into orepasses where the water from a high-pressure hose didn’t hit the other side and rock bolting loose stones.

Do tell me

more about these memories

I have many memories of events when working underground which can take a lot to explain but I will try to simplify a few.

Working in the orepasses. Leading up to the Christmas break of four weeks when maintenance was carried out, the ore passes to be worked on were cleaned down and inspected. To do this a miner would be lowered down the orepass on a bosun’s chair which consisted of a board and wire rope sings. I would sit in the chair and strap myself in with a safety belt. The winch driver would lift me up and lower me into the orepass to clean it down with a high pressure water hose. To let the winch driver know what I wanted to do I had a whistle. One to stop me, two for down and three for up, and to me it was fun. The water pressure would spin me around like a top and the only way to stop was to change direction of water spray. It got a bit hairy in the Twenty Level orepass as it had worn out to the size of a football field and the water didn’t reach the sides. I had to go a little lower and stand on a rock bench and then move over to do the job. Many beers drunk that night after work.

In another timber stope, the

chute was hung, meaning the rocks and dirt had formed a thick plug halfway up the chute. We needed to drill it from the top. Tiny

lowered me down on a bosun’s chair with a steel winch rope hand over hand for about twenty meters. I drilled several holes in the

plug with a pneumatic rock drill and charged them up. Tiny the pulled me up hand over hand. Yes, we broke the plug so we could use

the chute the next shift.

There were different classes applied to applicants to join the unions. An A grouper was born in Broken Hill. A B grouper had to be educated here, or their parents come from Broken Hill, or their parents be a member of the unions. I was a B Grouper because my father went to school in Broken Hill and worked in mines at Broken Hill, being a Miner and later a Diamond Driller.

Unions went hand

in hand with the mining industry as the miners fought for a better living from the dangerous occupation. The stately building of the

Trades Hall is now a reminder of Union domination in Broken Hill.

I talked to Chris, a Broken Hill local who worked in the mines for 24 years between 1976 and 2000.

Chris told me that when he

started, to get a job in Broken Hill you had to first qualify to meet union rules and criteria.

You must have had some frightening moments working underground.

Yes, there were accidents. In the event of an accident, the Platman would be notified and ring twelve bells to the winder driver and then the level number. The Platman then had total control over the cage movements.

In one incident, at the end of a shift on the 24 Level Jessie collapsed as he left the Crib Cuddy. A team of

men performed CPR whilst the cage came to pick him up with the rescue team. Jessie was put in the cage and as it disappeared out of

sight I could hear 1, 2, 3, 4, 5 as CPR was continued. On the surface ambulance officers pronounced him dead from possible heart attack.

Now a 4wd Ambulance can drive to the scene of an accident.

You mentioned explosives going off

I got fairly reckless

with explosives. To charge the back (top) holes in an open stope, I would stuff Gelignite down my work Flannel and climb a fourteen

foot ladder to load the holes with gelly and detonator. On one occasion there were four of us in a timber stope. I was charging up

and had spread electric detonators out on the boards for use. The scraper hoe was buried and I asked my workmate to move it. As he

applied power to the scraper winch, the timber moved forward allowing a rock to fall hitting the detonators. I heard the rattle of

the stone and yelled out run. I vividly remember the bright flashes as the detonators exploded behind me. One workmate received a

small piece of shrapnel in the arm. I had to pull another down who was climbing the rock wall.

How did you get to safety when

the detonators went off prematurely?

We could only run to the side of the stope; probably about 25 feet

How far did you

usually retreat?

Normally we were out on the plat waiting for the cage when explosives went off. This time it was only

detonators going off or I wouldn't be telling you. Now the entire level is cleared of personnel.

Was there a danger

or fear of collapse when underground?

There always is that danger. That is why we were working in a timber stop. Timber

to hold roof up

What about oxygen in the lower levels? How is and was air managed?

Air went down the cage skip shafts and

up ventilation shafts. Very big fans suck the air up special ventilation shafts.

Was the air tested for oxygen and carbon

dioxide amounts? Or just trust to luck?

Tested for flow and suitability for humans.

What about the larrikinism you remember?

There were many work mates who were the “life of the party” When working in a

dangerous occupation you have more fun at start of shift, lunch break and end of shift.

Tiny was full of fun, six foot six

tall and about 22 stone he could do anything. One day Camp Oven (short fat and black) was giving Tiny cheek. Tiny

grabbed him and put him headfirst in a 44-gallon drum and walked away, leaving two work boots kicking in the air.

In timbered

drives there was a gangway above the boards overhead so the truckers could empty the chutes of ore into the track to be taken to the

Orepass. This was the scene of another memorable incident.

One bloke (I forget his name) was known for saying ridiculous

things. Star Buss hid up in the gangway and dropped a sheet of yellow plastic down on the unaware man frightening the hell out of

him. I have never seen a yellow ghost move so fast.

Then there was the drink bubbler. One afternoon shift while waiting

for the cage, a small Italian man was trying to get a drink from the water bubbler. Every time he bent to drink the water stopped

and he would kick the bubbler. Turning to his Italian mate with his arms waving he called out

“Every time I try to drink the

water she go away.”

We were in fits of laughter as we could see Lambsie turning the water off from behind the pillar.

Thank

you Chris for sharing your stories.

Definitions:

Orepass is a vertical hole that ore is tipped into to get it from one level to the next. Orepasses go from

first level down to a crusher.

Platman is the cage operator. He rings the bells and travels in the cage (lift)

The Plat is

where the cage stops at each level

Crib Cuddy is an underground lunch area, usually a short tunnel off the side of the drive

(main tunnel)

Stope is where mining takes place